Super Spot has returned to our shop and is now for sale! We have owned this car three different times and for each owner, the car has jumped up several levels. Spot is now set-up perfectly, with all the best stuff. This is a rare opportunity to buy an extremely well-modified and sorted Bugeye Sprite. It would take a lot of money and time to build a new car this good so if you are looking for a hot Bugeye, check this one out.

We last sold this car in September of 2022, and completed more than $20K in upgrades before it left. That owner drove the car about 1500 miles, but health issues have forced him to move on to something different. Now you have a chance to take the reins!

Each prior owner has hired us to push the envelope with this car. In 2019, we performed a major build-out with multiple upgrades including swapping the lap belts to three point retractable belts, adding an air horn, rally clocks, larger dashboard mirror, spin-on oil filter conversion, LED lights all around, and nice center tunnel console in front of the shifter with Smiths volt and amp gauges. We changed the pinion seal and upgraded the cooling system with a six blade fan and aluminum radiator. We also added a powder-coated windshield frame and stanchions.

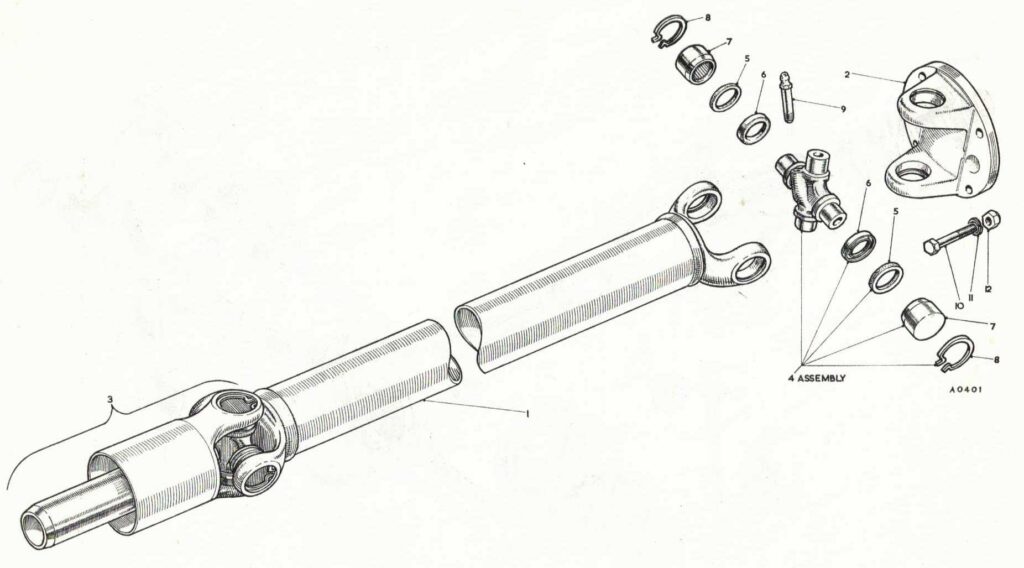

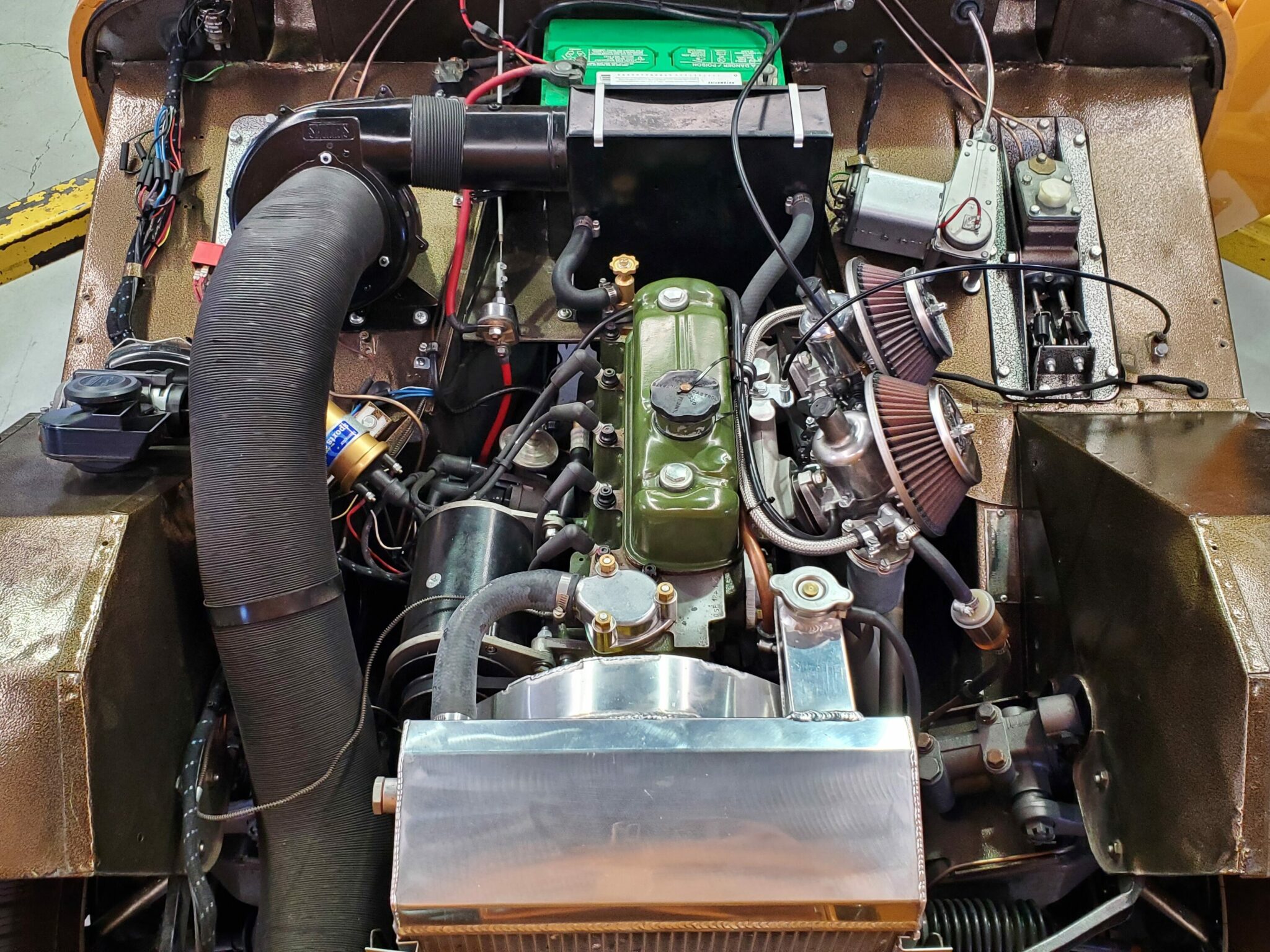

For the last client, we removed the engine and replaced it with a completely rebuilt 1380 CC Oselli performance engine mated to a Ford five-speed transmission. Add to that a lightened aluminum flywheel, larger clutch and the following additional great mods:

- rear disc brakes

- new rear wheel bearings

- new master cylinder and all new hydraulics

- all new hard and soft brake lines

- new shocks

- new front end and front disk brakes

- New 165 tires

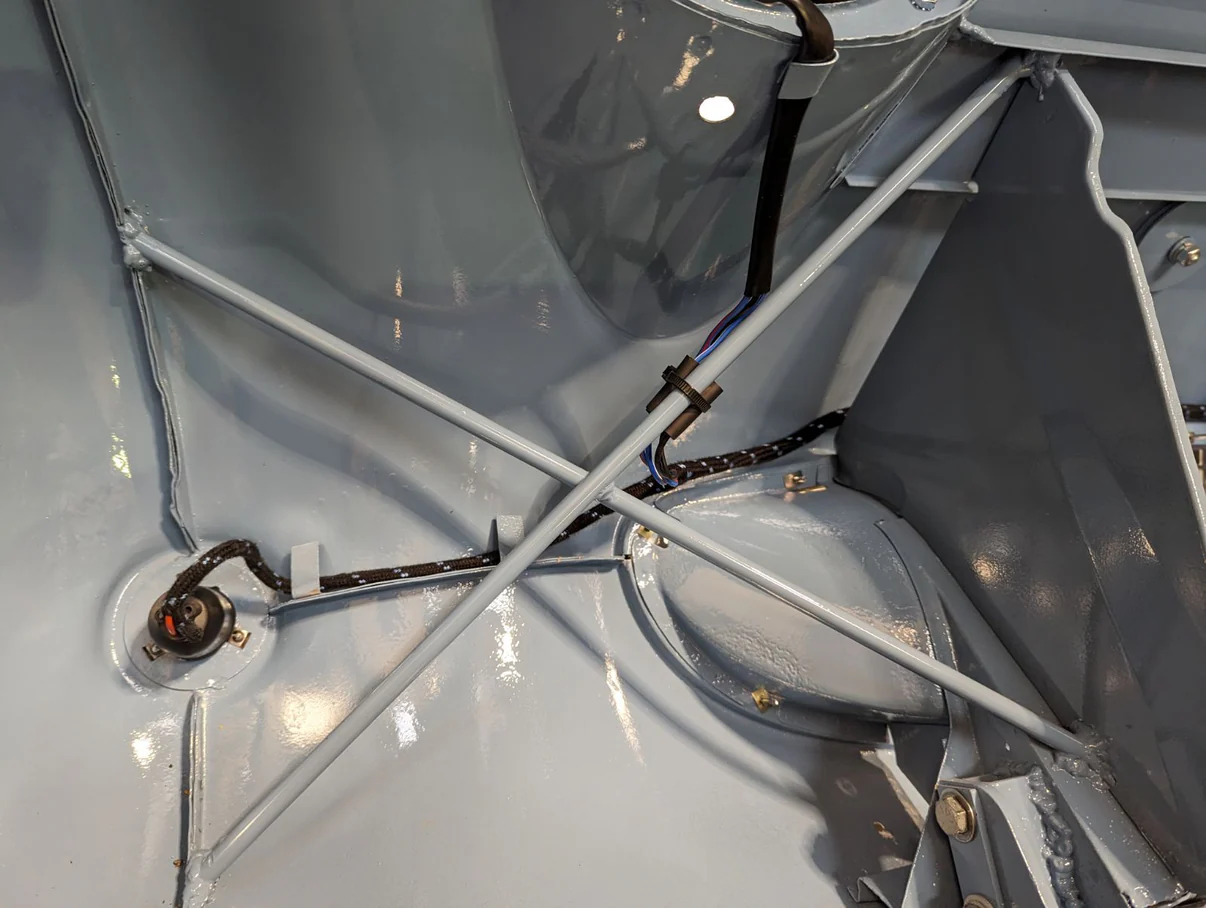

- flip nose kit with X braces and light bucket braces

- adjustable control arms for performance front wheel camber adjustment and improved handling

- new fuel tank and all related parts

- GPS speedo

- electronic taach

- stainless exhaust header

- dual tipped muffler

- New water hoses

- New hs2 carbs

- new k and n air filters

- custom hardura mats with contrasting thread

- custom tonneau with contrasting thread

- premium door pockets

- wind wings

- Momo Steering wheel

Super Spot comes with a convertible top and two-piece top bow, both in protective bags, as well as a set of Brooklands wind screens which can be installed in lieu of the full windshield should the new owner desire.

This is an awesome car with all the right upgrades you won’t want to miss! Click “read more” below for a full compliment of photographs and give us a call if Super Spot is right for you!

[Read more…] about Screaming 1380cc five-speed Super Sprite for sale! Long list of mods!